AR-15 Barrel Types: The Ultimate Guide to Materials, Profiles, and Performance

Are you piecing together your next AR build or swapping out that factory barrel for something with a bit more bite? Well, brace yourself, because diving into the world of AR-15 barrel types is like trying to drink from a firehose—endless specs, profiles, and metallurgy jargon coming at you from every direction.

But fear not!

We’re breaking it all down—builds, profiles, and enhancements—right down to the metallurgy, so you can pick the perfect pipe for your rifle. Whether you’re chasing tight groups, shaving weight, or just making sure your build looks the part, we’ve got you covered.

The Evolution of AR Barrels

From its battlefield debut in Vietnam as part of the original M16 loadout, the AR-15 barrel has seen its fair share of evolution—trimming weight, upgrading metallurgy, and adapting to the demands of modern warfare. These changes weren’t just for show; they sharpened accuracy, stabilized new ammunition, and reinforced the barrel against the unforgiving elements of combat.

But the impact didn’t stop there. These military-driven upgrades didn’t just give American soldiers a tougher, more reliable rifle—they set the stage for what would become America’s Rifle.

Over the years, the AR platform has only grown leaner, meaner, and more modular, and its barrel? Well, that’s where some of the most impressive refinements in production and performance have taken place.

More for AR-15 Owners: Best AR-15 Barrels, Best AR-15s, Everything You Need to Know Before Buying Your First AR-15

Material Types

The type of metal used in your rifle’s barrel affects everything from tolerances and rifling methods to heat resistance and overall performance. Some materials focus on affordability, others on longevity, and a few manage to balance both. Here’s a rundown of the most common barrel materials in the AR-15 world:

4140 Chromoly Steel

Basic, budget-friendly, and built for casual use.

The 4140 alloy is about as basic as gun steel gets—weldable, heat-treatable, and cheap. With a mix of carbon and chromium, it offers a decent blend of tensile strength and durability without hitting your wallet too hard. It’s a solid choice for a budget build or a beater gun, but let’s be honest—it’s the entry-level option. At the end of the day, 4140 is on the lower rung of barrel materials.

4150 Chromoly Steel

Stronger, tougher, and built for abuse.

Step up to 4150, and you’re getting a tougher, more heat-resistant alloy thanks to the addition of vanadium. This is the go-to steel for military barrels, built to withstand high rates of fire and harsher conditions. It’s pricier than 4140, but as the saying goes, you get what you pay for—better wear resistance, longer lifespan, and a barrel that can take a beating.

Stainless Steel

Precision-focused, corrosion-resistant, and made for marksmen.

If accuracy is the name of the game, stainless steel is your player. It shrugs off corrosion better than chromoly and delivers superior precision, making it a favorite for marksmen and competition shooters. It also handles heat more efficiently, though that comes at a cost—literally.

The tradeoff? Stainless steel isn’t as flexible as chromoly, meaning it won’t hold up as well under sustained or full-auto fire. Over time, it’s more prone to wear and tear, making it a great choice for precision work but not the best pick for high-volume abuse.

While barrel material sets the foundation for durability and performance, its profile—or contour—plays a crucial role in weight, balance, and heat dissipation.

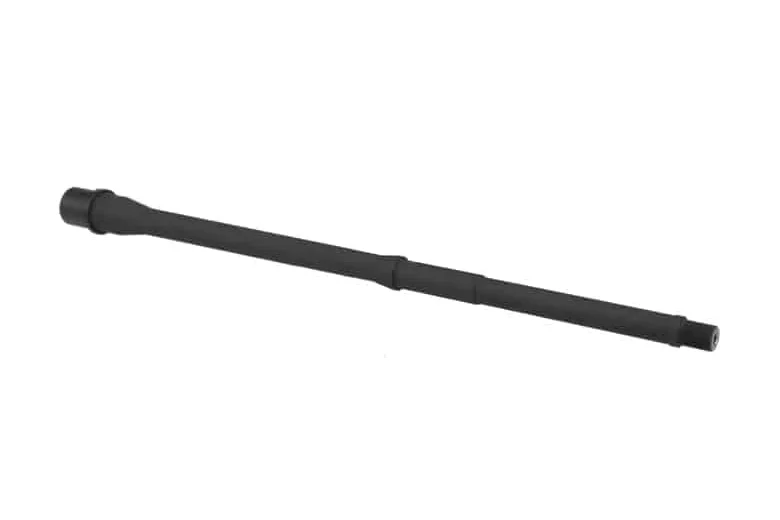

Profile Types (Contours)

A barrel’s profile refers to the thickness and contour of the metal along its length, influencing everything from handling and weight to heat dissipation and accuracy. Some profiles prioritize agility, others durability, and a few aim for a balance between the two. Let’s break down the most common AR-15 barrel profiles:

Lightweight/Pencil

Light, nimble, and quick on the draw—but not built for the heat.

The lightweight or “pencil” profile shaves ounces for better maneuverability, making it ideal for shooters who prioritize speed and handling. But here’s the tradeoff: with its slimmer diameter, this profile heats up fast under sustained fire, which can lead to accuracy degradation. If your shooting style leans toward controlled, deliberate shots rather than mag dumps, the pencil profile stands out as a solid option.

Government

A nod to the M16, balancing durability with battlefield versatility.

Modeled after the Vietnam-era M16, the government profile takes cues from its military lineage. It bulks up where it matters—especially in front of the gas block—offering better heat dispersion, durability, and accuracy compared to the pencil profile. The added material helps balance the rifle’s weight distribution, making it a jack-of-all-trades that performs well across a variety of shooting scenarios, from training drills to home defense.

M4

Compact, sturdy, and built for the battlefield.

Designed specifically for the M4 carbine, this profile is essentially a shorter, slightly modified version of the government barrel. It features the signature cutout for an M203 grenade launcher—though outside of military use, this detail is mostly for aesthetics.

The downside? A shorter barrel means higher muzzle flash and faster heat buildup, which can affect long-range performance. Still, thanks to its rugged build and solid weight distribution, the M4 profile remains a trusted choice among military, law enforcement, and civilian shooters alike—especially for home defense setups.

Bull

The heavyweight champ of precision shooting.

The bull barrel is all about mass—more metal means better stability, reduced recoil, and increased heat resistance. But with great weight comes great imbalance. This profile is not for high-mobility applications; lugging one around all day isn’t exactly fun. While bull barrels resist overheating better than their skinnier counterparts, once they do heat up, they take forever to cool down. Because of this, they’re best suited for precision shooting, benchrest setups, and hunting small game—any scenario where accuracy outweighs portability.

Heavy (HBAR)

A step down from bull barrels, but still no featherweight.

The Heavy Barrel Automatic Rifle (HBAR) is a slightly leaner alternative to the bull profile. Like its heftier cousin, it resists overheating and helps manage recoil. However, unlike the bull barrel, the HBAR offers slightly better balance, making it a more viable option for tactical applications—though it’s still on the heavier side. That extra weight means better shot consistency, but it’s not ideal for long treks through the backcountry. More often than not, HBARs are found on scoped defensive rifles or belt-fed setups where sustained fire is a factor.

SOCOM

Heavy where it counts, lighter where it matters.

Designed to withstand the rigors of combat, the SOCOM profile takes inspiration from the M4A1 carbine, maintaining a thickness similar to heavy barrels while shedding unnecessary weight where possible. This results in better durability and heat dispersion without making the rifle feel like an anchor. SOCOM barrels are also optimized for suppressors, which only adds to their appeal—both functionally and for that “tacticool” factor.

One notable downside? Like most shorter barrels, the SOCOM profile struggles with muzzle flash, making a flash hider or suppressor a welcome addition. And, much like the M4, it originally included a grenade launcher cutout—though that feature is becoming rarer on civilian models. Some shooters like the aesthetic, while others see it as extra weight with no practical use.

While barrel profile affects weight, balance, and heat management, it’s the rifling inside that truly dictates how your rounds behave in flight. From twist rates to groove patterns, rifling plays a critical role in stabilizing bullets and ensuring accuracy downrange.

If you really want to get nerdy, this is where the science kicks in—because the way those tiny grooves are cut into your barrel can mean the difference between a stable, straight-flying round and a bullet tumbling off course. Let’s break it down.

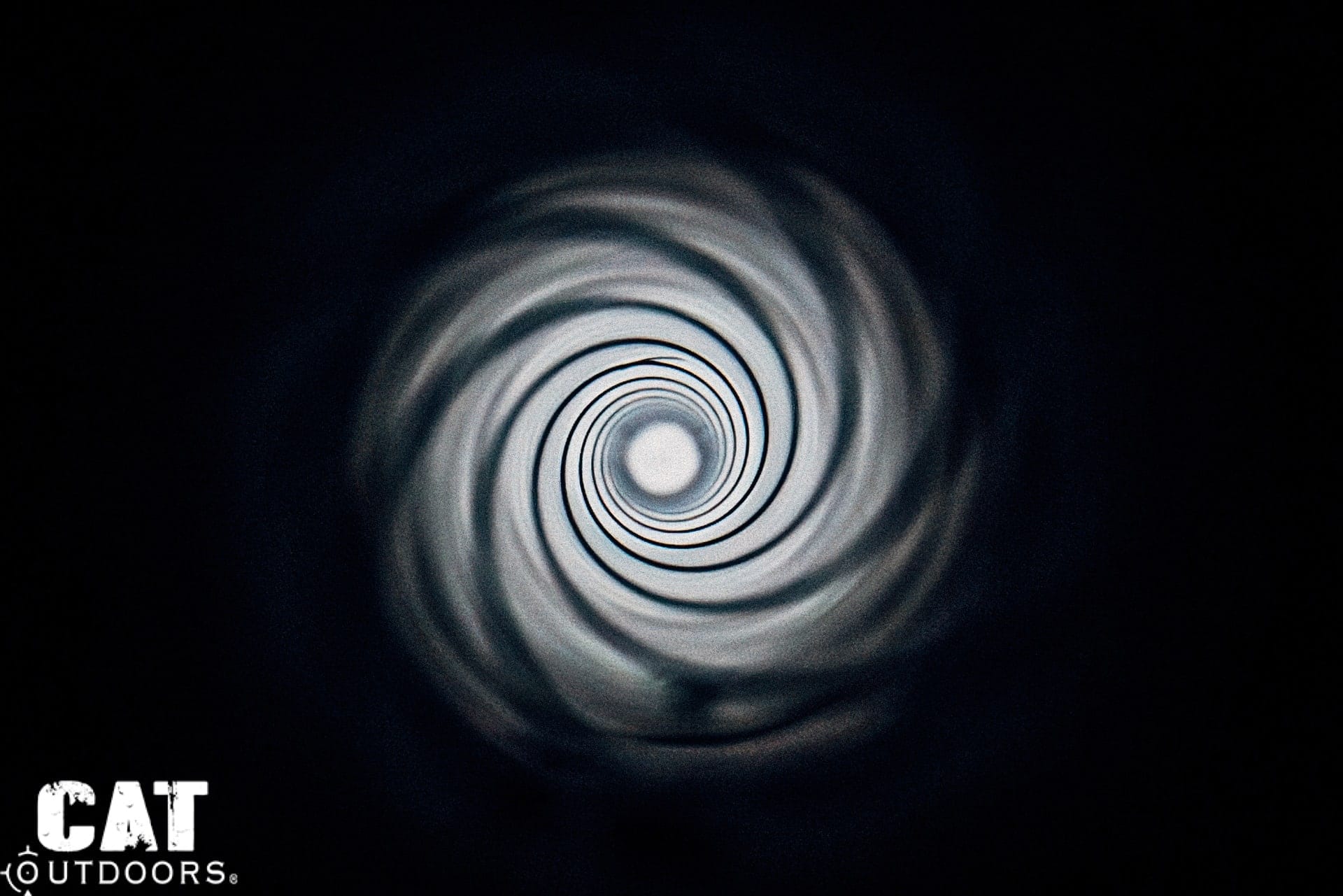

Rifling

If barrel profile dictates how your rifle feels in hand, rifling determines how well it delivers rounds on target. These spiral grooves cut into the bore are what give a bullet its spin, keeping it stable in flight and preventing it from tumbling off course.

Cold Hammer Forged (CHF)

Tough, durable, and built to last—but not without its limits.

The CHF process starts with a barrel blank placed into a high-pressure CNC machine, where it’s hammered into shape around a mandrel that imprints the rifling pattern. This method is expensive but produces highly durable barrels with excellent longevity and consistent accuracy.

That said, CHF barrels don’t necessarily outshine other methods in performance. Their biggest advantage is the ability to cut complex rifling patterns that standard button rifling can’t achieve. Beyond that, it’s simply another option in the world of AR-15 barrels.

Button Rifling

Affordable, effective, and widely used.

Button rifling uses a metal tool shaped like a bullet casing—called a rifling button—that’s either pushed or pulled through the pre-drilled bore. This process engraves the rifling into the barrel using extreme hydraulic pressure, ensuring proper bullet stabilization and consistent shot placement.

It’s a cost-effective and accurate rifling method, but there’s a tradeoff: button rifling lacks flexibility. Each new groove pattern or twist rate requires a different button, which can drive up costs. And unlike CHF, it can’t create the intricate patterns possible with CNC machining.

Cut Rifling

The old-school precision method still favored by serious marksmen.

Dating back to 16th-century Germany, cut rifling is one of the oldest and most precise methods available. A machine cutter meticulously etches each groove, one pass at a time, ensuring unparalleled consistency. Though timef-consuming and expensive, this method produces some of the most accurate barrels in existence, making it a top choice for competition shooters who demand tight tolerances.

Broach Rifling

A relic of military mass production.

Broach rifling uses multiple blades to cut grooves into a cold barrel simultaneously, making it significantly faster than single-blade cut rifling. This efficiency made it the go-to method for military rifle production in the early 20th century.

However, broaching was eventually phased out in favor of button rifling, which proved to be more cost-effective and delivered better accuracy. While rarely seen in modern AR barrels, some handgun manufacturers have adopted this method for specific models.

5R Rifling

A modern twist on an old design.

Developed by Faxon Firearms, 5R rifling was designed to address the wear and tear of conventional rifling while improving accuracy. By using a gentler angle between lands and grooves, it reduces bullet deformation and minimizes fouling, leading to a longer-lasting barrel with better shot consistency.

While 5R has its advantages, it’s still relatively new and not widely available. Additionally, it only supports certain types of AR ammunition, which may limit its appeal to some shooters.

Polygonal Rifling

Smoother, faster, and easier to clean—but not for everyone.

Instead of traditional sharp-edged lands and grooves, polygonal rifling uses gently rounded hills and valleys to guide the bullet. This smoother design reduces friction, increases velocity, and improves gas sealing, resulting in a more efficient propulsion of the bullet.

It also extends barrel life and makes cleaning easier, as there are fewer sharp edges to accumulate fouling. However, polygonal rifling isn’t widely used in AR-15 barrels due to its higher cost and machining complexity. It also doesn’t perform well with certain types of ammunition—particularly lead rounds—and tends to impact accuracy in ways that make it better suited for handguns, like Glock pistols, rather than precision rifles.

Electrochemical Rifling (ECM)

Cutting metal with science—literally.

This process uses an electrochemical machine (ECM) to dissolve metal in a controlled manner. A negatively charged rifling cathode is inserted into a saltwater-submerged barrel blank, and an electrical current etches the grooves into the bore.

The result? A rifling process with zero mechanical stress that enhances barrel durability. ECM also allows for intricate rifling patterns that traditional machining methods can’t replicate. However, the process is expensive, generates waste that requires careful disposal, and has raised environmental concerns. While it has been experimented with in AR manufacturing, most shooters stick with conventional methods due to ECM’s cost and complexity.

Cation Rifling

A futuristic experiment—or the next big thing?

Still in its early stages, cation rifling uses acid-soaked rotating wipes to etch grooves into a barrel blank. The acid gradually eats away at the bore’s surface, creating rifling with precise depth, width, and twist rates. A neutralizing agent is then used to halt the acid’s effects.

Early prototypes have shown promising tolerances, and this method can cut through metal that even traditional rifling techniques struggle with. However, the need for specialized chemicals and storage, along with the associated costs, makes it an expensive and experimental process—for now.

Rifling keeps your shots on target, but a good finish keeps your barrel in the fight. Corrosion, heat, and wear are constant threats—and this is where the right coating makes all the difference.

Barrel Finishes & Coatings

A barrel’s finish isn’t just for looks—it’s a critical factor in durability, corrosion resistance, and long-term performance. The right coating can mean the difference between a barrel that shrugs off the elements and one that rusts out after a few hard range days. Some finishes focus on extreme protection, while others are more about aesthetics.

Let’s break down the most common AR barrel coatings and what they bring to the table.

Chrome-Lined

Built for battle, but not without tradeoffs.

A chrome-lined bore enhances durability, heat resistance, and corrosion protection—making it a staple for military service rifles. The hard chrome layer significantly reduces internal wear and makes cleaning a breeze, ensuring a longer-lasting barrel under heavy use.

The downside? Chrome lining adds a thin but uneven layer to the bore, which can have a minor impact on accuracy. It’s also one of the pricier treatments. Still, if longevity and reliability are the goal, a chrome-lined barrel is tough to beat.

Melonite/Nitride

Extreme hardness, better corrosion resistance, and no accuracy loss.

Melonite, also known as nitride, uses a heat-treatment process that diffuses nitrogen into the barrel steel, creating a super-hard, corrosion-resistant surface. Unlike chrome lining, it doesn’t add material to the bore, so there’s no impact on accuracy.

This process requires precision to avoid over-saturating the metal, but when done right, a nitride-treated barrel offers exceptional longevity without the downsides of chrome lining. The cost is relatively high, but it’s a solid choice for shooters who want a tough, low-maintenance barrel without sacrificing performance.

Bluing

Classic aesthetics, but minimal protection.

Bluing applies a layer of black iron oxide to the barrel’s surface, giving it that deep, glossy blue-black finish. While it provides some corrosion resistance, blued barrels still require regular oiling to prevent rust—especially in humid environments.

In reality, bluing is more about looks than function. It’s a classic finish for traditional firearms but falls short compared to modern coatings in terms of long-term protection. Hot bluing offers slightly better rust resistance, but like its standard counterpart, it still requires frequent maintenance.

Phosphate (Parkerizing)

A rugged, military-grade finish with solid corrosion resistance.

Parkerizing, also known as phosphating, applies a chemical coating that helps prevent moisture buildup and corrosion. It also creates a non-reflective, matte finish—ideal for tactical applications.

While parkerizing provides more protection than bluing, it’s still not as durable as nitride or chrome lining. Scratches are common, though they can be minimized with regular oiling. Over time, areas exposed to high friction will wear faster, but for a cost-effective, no-nonsense finish, phosphate is a reliable option.

Stainless Steel (Natural Finish)

No coating, just raw precision.

Stainless steel barrels rely on their natural corrosion resistance rather than any applied coating. They offer excellent accuracy and precision but tend to show wear, blemishes, and rust over time—especially without proper maintenance.

While stainless barrels have their advantages in terms of shot consistency, they generally don’t last as long as treated steel barrels. If accuracy is your top priority and you don’t mind some extra upkeep, stainless steel is a solid choice.

Cerakote

Custom looks, serious protection.

Cerakote is a ceramic-based coating that bonds to various surfaces, including steel, aluminum, and polymer. It provides excellent resistance to corrosion, heat, and wear while offering an almost unlimited range of colors and patterns for customization.

However, Cerakote requires careful application. Too much, and it can interfere with tolerances on precision parts. While it can be applied at home, professional application ensures a thinner, more even coat. If you’re interested in DIY Cerakote, check out our guide on how to apply it yourself.

Anodizing

Tough, durable, but limited to aluminum barrels.

Anodizing, or “hardcoat anodizing,” is a popular electrochemical treatment that enhances the durability and corrosion resistance of aluminum barrels and parts. Unlike Cerakote, anodizing doesn’t adhere well to steel or polymer, making it a finish specifically for aluminum-based AR components.

Available in multiple color dyes, anodizing offers customization options while reinforcing the barrel’s surface. However, it’s a labor-intensive and costly process that requires professional application. The chemicals involved are also hazardous, making this a less environmentally friendly option.

A good finish protects your barrel, but what if you want to take things a step further? That’s where barrel enhancements come into play.

Enhancements

Whether you’re looking to shave off weight, improve heat dissipation, or simply give your rifle a more aggressive look, these modifications offer both functional and aesthetic benefits. Some are tried-and-true performance boosters, while others spark endless debates over whether they actually make a difference.

Let’s break down some of the most popular barrel enhancements and see which ones are worth considering.

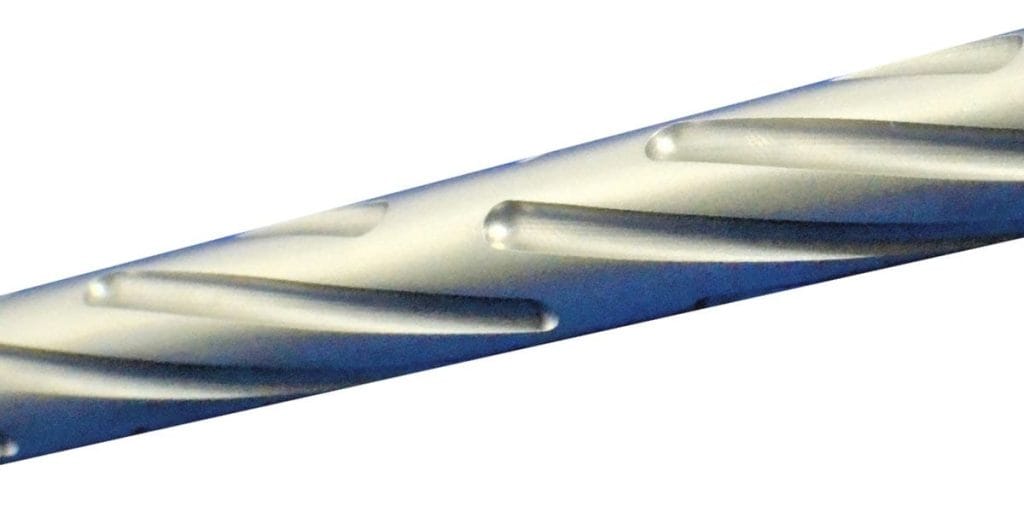

Fluting

Fluting isn’t just for show—it’s a machining process that removes material from the exterior of the barrel to reduce weight and improve cooling. The more intricate the design, the higher the price tag, but for many shooters, the benefits outweigh the cost. Here’s a breakdown of the most common fluting types:

Straight Fluting

Simple, functional, and cost-effective.

Straight fluting consists of shallow, longitudinal cuts along the barrel’s exterior. It shaves off some weight and helps with heat dissipation, though not as effectively as more elaborate fluting patterns. If you’re looking for a no-frills enhancement, this is a solid option.

Spiral/Helical Fluting

A step up in both form and function.

This type of fluting features a continuous, twisting pattern along the barrel, resembling a helix. The design improves cooling efficiency over straight fluting and offers similar weight reduction. Plus, it’s a favorite among shooters who appreciate its unique aesthetic—though cleaning those deep grooves takes a bit more effort.

Interrupted Fluting

A balance between rigidity and weight reduction.

Instead of a continuous pattern, interrupted fluting leaves sections of the barrel unfluted. This maintains a greater level of structural integrity while still cutting weight. However, because some of the barrel surface remains untouched, it doesn’t dissipate heat as well as fully fluted designs.

Diamond Fluting

Distinctive looks with functional benefits.

Diamond fluting adds a custom, crisscrossed pattern to the barrel, offering a balance of weight reduction, cooling, and durability. The precision machining required for this design makes it one of the more expensive options, but the combination of function and aesthetics makes it a popular choice.

Varied Depth Fluting

More customization, but at a cost.

This type of fluting incorporates cuts of varying depths along the barrel, improving barrel harmonics and potentially enhancing accuracy. However, if not executed properly, uneven stress distribution can lead to performance issues. Precision machining is key, making this a more premium enhancement.

Dimpled Barrels

More heat dissipation, but does it really help?

Dimpling involves machining evenly spaced indentations across the barrel’s surface to reduce weight and improve cooling. Some shooters swear by the benefits, claiming better heat dispersion and increased rigidity, which theoretically improves accuracy.

However, others argue that the effects are minimal at best and that dimpling can weaken the barrel’s structure. While it certainly gives the rifle a unique look, its real-world advantages remain up for debate. If you’re considering a dimpled barrel, do your homework before committing to the modification.

Carbon Fiber Barrels

Lightweight, corrosion-resistant, and built for precision.

Unlike traditional steel barrels, carbon fiber barrels use a lightweight composite material that offers superior heat dissipation, reduced harmonic vibration, and complete resistance to rust and corrosion. These benefits make them an excellent choice for precision shooting and long-range applications.

However, carbon fiber barrels have their drawbacks. They don’t handle sustained fire as well as steel, and they’re more prone to damage from rough handling. While excellent for hunting and competition shooting, they aren’t the best choice for high-volume or tactical use. Add in the premium price tag, and it’s clear that carbon fiber barrels cater to a specific type of shooter.

Free-Floating Handguard

Not a barrel enhancement, but a serious accuracy booster.

While not technically a barrel modification, a free-floating handguard can have a noticeable impact on performance. Unlike traditional handguards that make contact with the barrel, a free-floater attaches only to the upper receiver, eliminating pressure points that could affect accuracy.

Additionally, it provides more stability for mounted accessories like optics, grips, and bipods, ensuring they stay locked in place during rapid fire. With extra real estate for hand placement and improved shot consistency, a free-floating handguard is a must-have for serious shooters looking to maximize precision.

More from CAT Outdoors

FINAL THOUGHTS ON AR-15 BARREL TYPES

At the end of the day, your barrel is the heart of your rifle—it dictates accuracy, durability, and how much abuse your AR can handle before it starts begging for mercy. Whether you’re building a budget-friendly beater or a high-performance tack driver, your choice of material, profile, rifling, finish, and enhancements all play a role in how your rifle performs when it matters most.

Want something simple and reliable? Stick with 4150 chromoly and call it a day. Chasing pinpoint precision? Stainless steel is your best friend—just don’t mag dump it into an early grave. Need to shave weight or maximize heat dissipation? Fluting, dimpling, or even a carbon fiber barrel could be worth a look. And if you really want to nerd out over coatings, go for nitride or chrome lining and keep your barrel running long after your ammo supply runs dry.

Once you know what barrel suits your needs, choosing from the best AR-15 rifles can ensure your new build starts with a top-quality foundation.

Ultimately, there’s no one-size-fits-all answer. Your barrel choice should match how you actually use your rifle—not just what looks good in a product photo. So, do your research, pick wisely, and remember: a great barrel won’t make you a great shooter, but a bad one can definitely make you a worse one.

Aaron Basiliere is a staunch 2A advocate, a firearms researcher, and one of the principal content creators here at CAT Outdoors. He has written in multiple professional capacities for the last 16 years. He has a BA in English Writing from the University of Wisconsin. When not writing for CAT Outdoors he enjoys drinking coffee, watching documentaries, and spending time with his family and friends.